Views: 429 Author: CLW Group-Albert Du Publish Time: 2018-02-01 Origin: https://www.clwvehicle.com/Water-Spraying-Truck-pl571870.html

How to operate the water bowser and water spraying truck?

1.Brief Introduction of working principle and structure of water tank truck

(1)structure drawing

water canon Sprinkler Tnak Truck chassis

Rear Sprinkler Pump system and pipeline Front Sprinkler

2. Chassis

Water bowser tank truck adopts second class chassis.

3. Tank

Structure shown as below drawing, tank shape can be oval or bread, made of carbon steel. The tank is adopted 2~3 compartments, the compartment board has holes underneath, whose function is to reduce the shock of wave to the tank while moving. To proof of corrosion, tank inside is non-toxic and anti-corrosion treated, and tank surface is painted anti-corrosive and decorative paint .

1、tank head 2.hand rail 3、manhole 4、ladder 5、rings 6. Support 7.secondary beam 8. Tank 9. Water canon 10.compartment board、anti-wave board 11. Burette

4. Manhole

The round manhole cover is adopted with breath hole, which keeps the pressure of the tank inside and outside equal when filling in water.

1. Handle 2、small cover 3、large cover 4.rotary pin

5, PTO

The PTO of water truck series is controlled by switch. When Open the pneumatic switch, the gear of PTO enters into engage position. Through the shaft drive the pump working. When close the pneumatic switch, the pump stops working immediately.

6, Pump

The structure principle and maintenance are attached.please find attachment “pump instruction manual”

7, Ball valve

There are usually one piece of four-position tri-link ball valve and six pieces of duel-link ball valve in water truck. The four-position tri-link ball valve is a kind of ball valve which can shape three liquid channels. This ball valve can quickly change the direction of liquid. It is widely used in non-corrosive medium. It is through the position of handle to makes any of two holes open or close.

1-handle

2-O-shape sealing ring

3-valve stem

4-ball valve

5-O-shape sealing ring

6-sealing

7-adjustment base

8-valve

8.Sprinkler

The front of the car is equipped with duckbill nozzle or round red mouth, the back is equipped with a cylindrical watering mound, side showers.Rear of car is mounted with antiaircraft gun(Optional).Sprinklers are generally used for washing streets, eliminating the dust and cooling air.the water sprinkler can be adjusted to change Sprinkler spraying direction and angle, antiaircraft gun can be used to effect urban and rural areas and emergency fire engines. Shower nozzle can be poured down Middle of the road washing dust and clean the air.

9. Accessory list:

PTO 1

Water Pump 80YHCB-60/ 60YHCB-30 1

Aluminum Alloy Ball Valve Φ50 1

3-Way Ball valve Φ65 1

3-way filter net Φ65 1

stainless steel ball valve Φ25/Φ50 7

flange outlet Φ65 2

sprinkler gun 1

fire hydrant 1

Above configuration is for standard configuration, the customers can change the configurations if have any special requirements.

Operation Instructions

1.Preparation before using.

(1).Check the oil surface of lubrication in transmission, based on bottom edge of oil surface plug hole, adding gear oil when not enough.

(2). Check the transmission lever, let it be in neutral position, and check the controlling lever position of PTO,keep it be horizontal and right position, then check the accelerator controller, make it to be minimum.

2.Operation for Water Pump and PTO

(1).Start, connect the related pipelines well, start the engine,when the vehicle pressure gauge reads at 0.3Mpa, press the clutch pedal, and release the clutch slowly (If too fast, PTO and transmission will be damaged), then put it into gear.Through the oil throttle controller, it can control the working speed of water pump.

(2).Stop, boost the oil throttle controller, adjust it to a minimum, press the clutch pedal,and then keep the controlling switch of PTO back to the previous position, make the PTO box out of gears.

3.Check after using the water spraying truck

(1) Check if returning the controlling switch of PTO, and check if the oil throttle is on the minimum position.

(2) Check if the position for valve handle lever is “off” state.

4. Instruction for Different Operation of water tank truck

1) Refilling Water Tanker truck.

a. Filling in Running Water: Stop water truck in designated position, open the manhole, insert the water hose into manhole, turn on the water till the tanker is totally full.

b. Filling in open water: Using pump to suck water into the tanker. Main process:

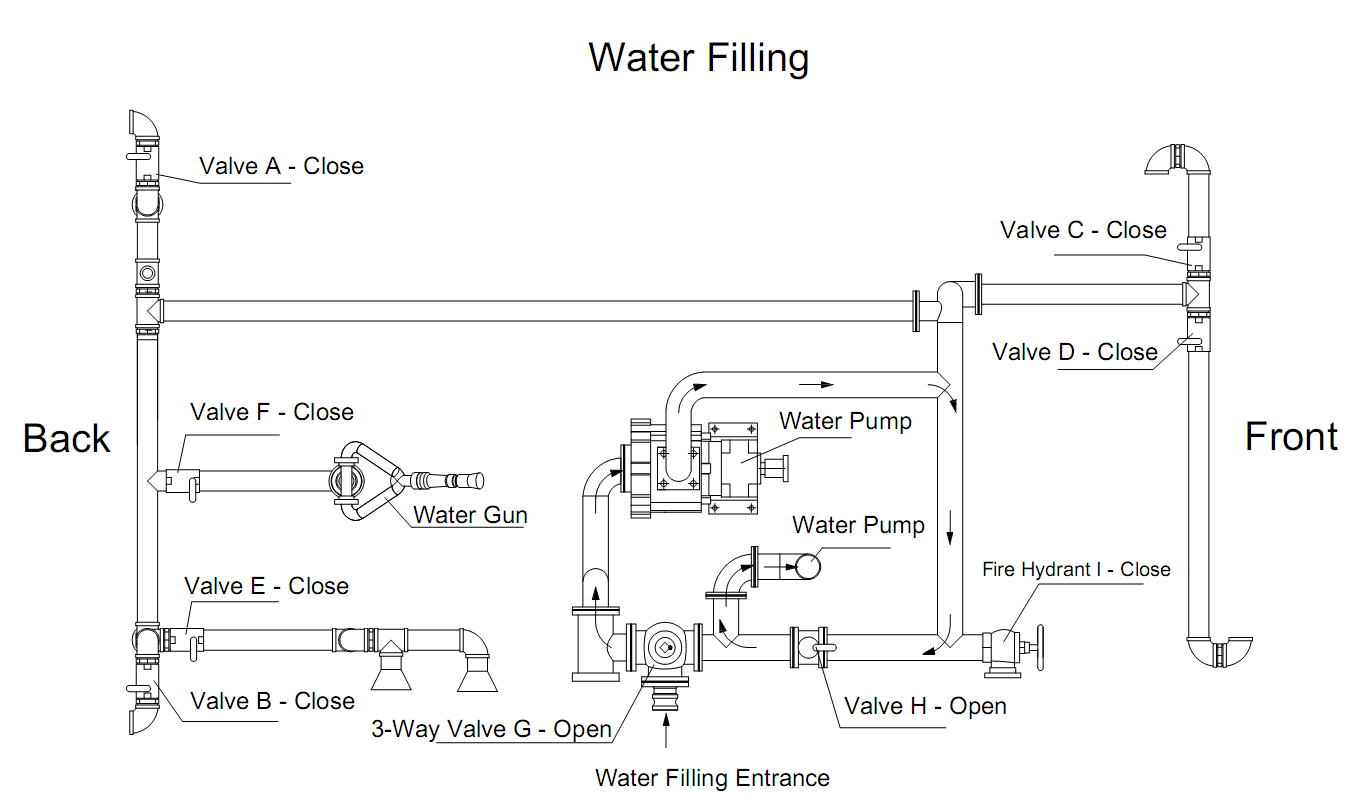

Connect a water hose in open of "3 Way Valve G", turn the valve into open position horizontally as below diagram (note: 3 Way Valve is close if the handle face same direct with dent mark on the valve), close stainless steel valve A, B, C, D, E, F and Fire Hydrant I,open Aluminum Valve H; go to cabin and press down the clutch, open the PTO switch, gradually release the clutch (Note: don't release too quick, or it will ruin PTO and Gearbox), then pump start to work and fill water into the tanker, close all the open valves.

Water Flowing Ways: Entering from 3 Way Valve G, pass the filter & pump, through Aluminum Valve H, finally into the tanker. (Valve A, B, C, D, E, F, G are all closed.)

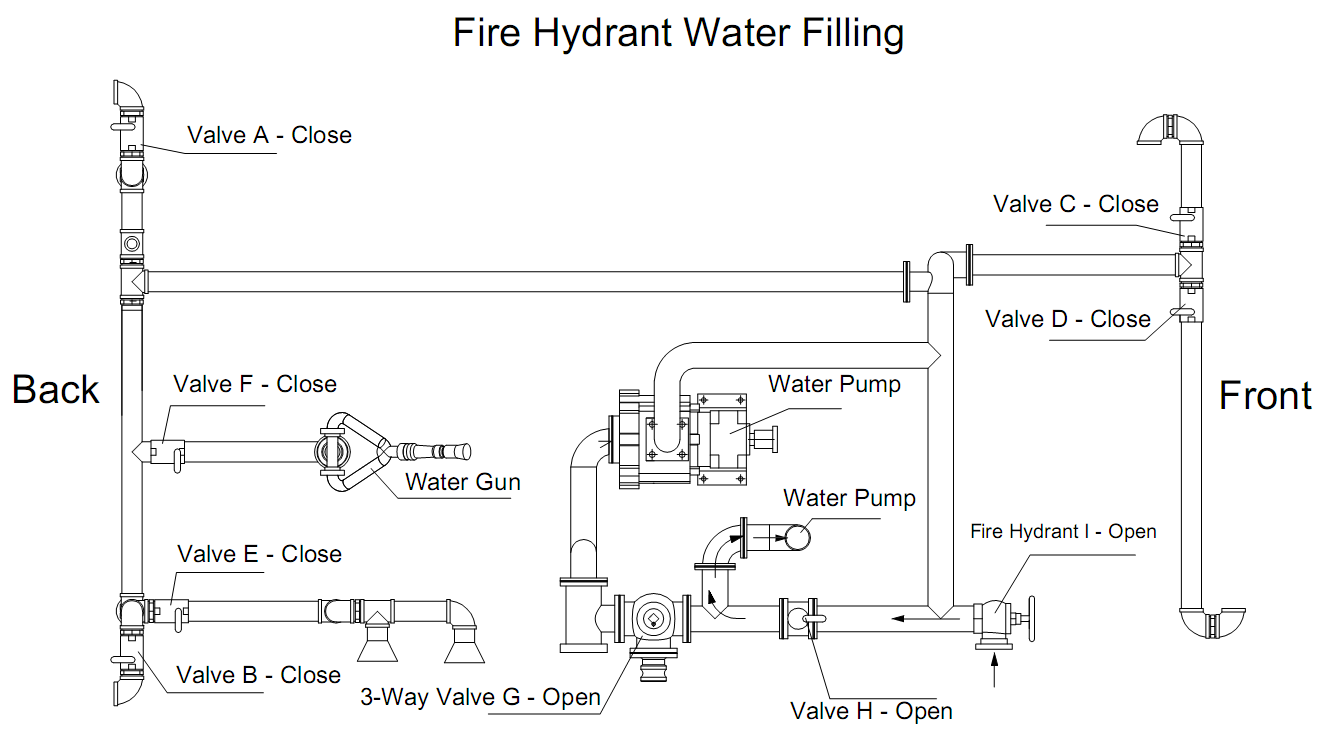

C. Filling with Fire Hydrant Water: Connect the fire hydrant hose in "Fire Hydrant I", close the valve and turn the "3 Way Valve G" to vertical position, then water will flow into the tanker.

Water Flowing Ways: Entering from Fire Hydrant I, through Aluminum Valve H, finally into the tanker. (Valve A, B, C, D, E, F, G, H are all closed.)

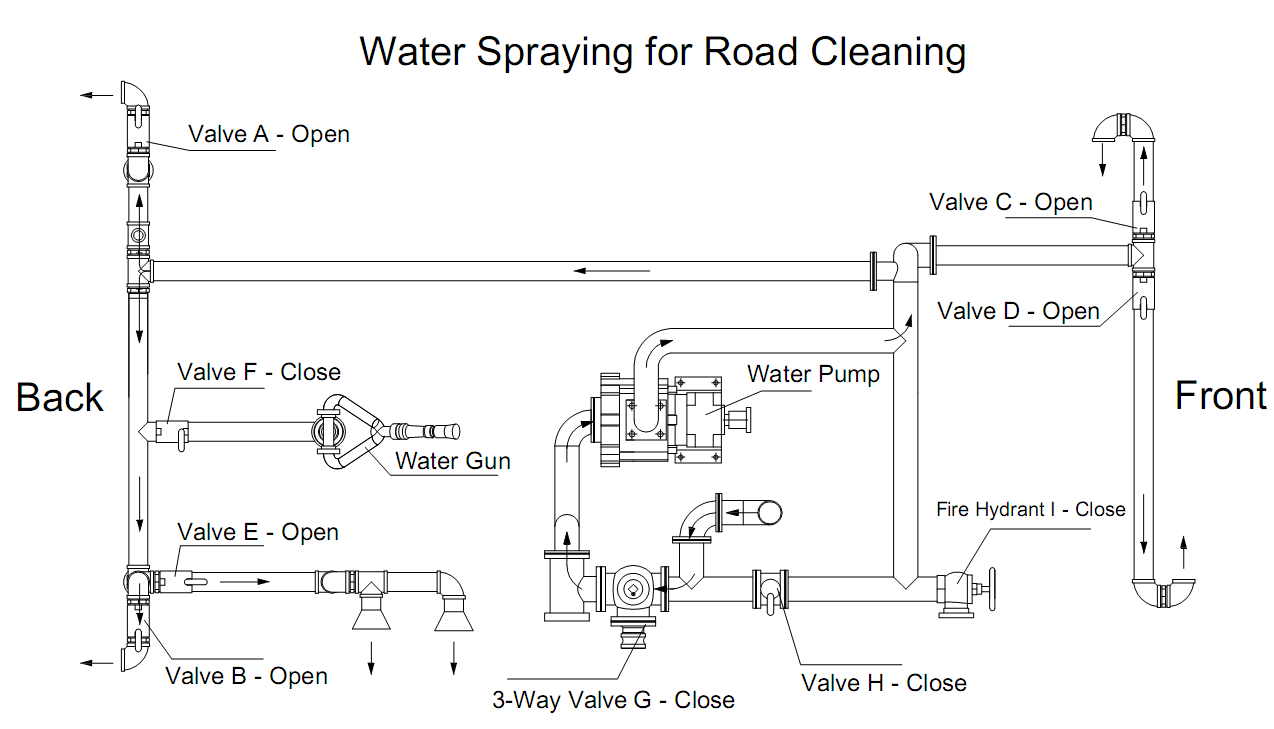

(2) Water Spraying Operation of water bowser

To Spray water on the road, the main process: Turn 3 Way Valve G to vertical postion (note: 3 Way Valve is close if the handle face same direct with dent mark on the valve), Close Aluminum Valve H & Fire Hydrant I, open stainless valve A, B, C, D, E;go to cabin and press down the clutch, open the PTO switch, gradually release the clutch (Note: don't release too quick, or it will ruin PTO and Gearbox), then pump start to work and start the spraying water. Open Valve F to water high tree or grass far distance beside the road.

Water Flowing Ways: flow out of the tanker, through 3 Way Valve G, water filter & pump, front & back spraying hose. (H & I Valve are closed)

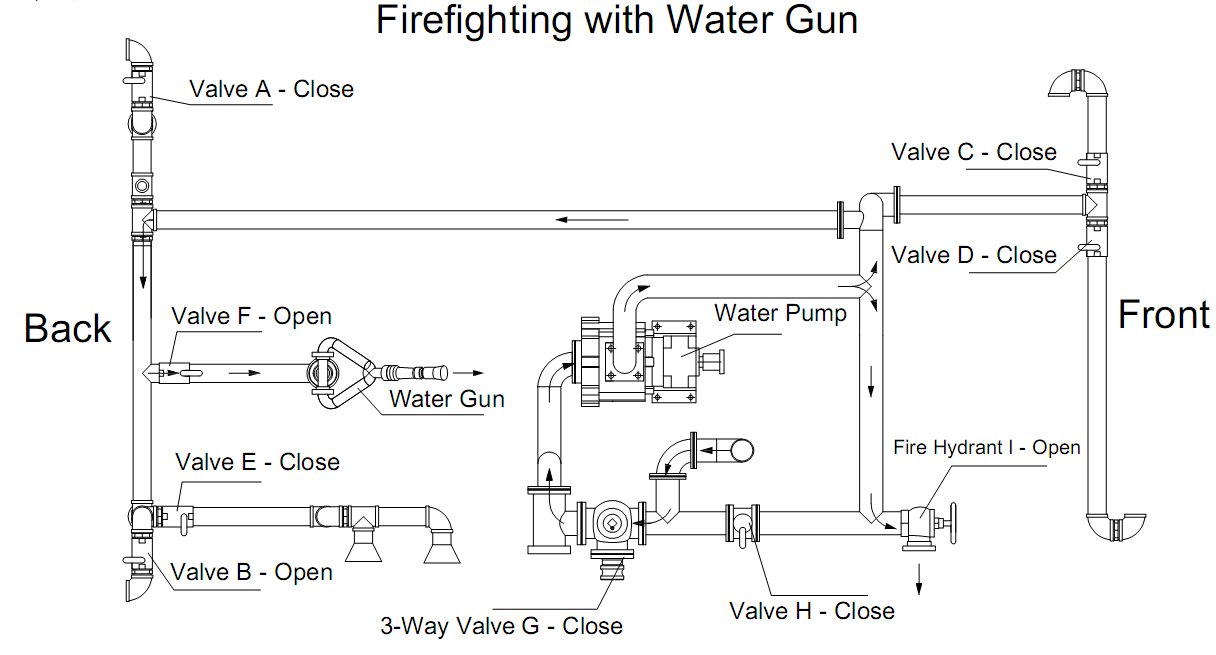

(3) Firefighting Operation

In any fire emergency, the water truck can use to extinguish fire with water gun at connecting on fire hydrant water. The main operation process: Turn 3 Way Valve G to vertical position (note: 3 Way Valve is close if the handle face same direct with dent mark on the valve), close stainless steel valve A, B, C, D, E and aluminum valve H, open fire hydrant I and stainless steel valve F; go to cabin and press down the clutch, open the PTO switch, gradually release the clutch (Note: don't release too quick, or it will ruin PTO and Gearbox), then pump start to work, water gun and fire hydrant can use to extinguish fire

Water Flowing Ways: flow out of the tanker, through 3 Way Valve G, water filter & pump, water gun F & fire hydrant I. (Valve A, B, C, D, E, H are closed)

(4) Mobile Pump Station of water spraying truck

As the truck have water pump, it can become mobile pump station if needed. Main process: Connect hose in 3 Way Valve G, Turn 3 Way Valve G to vertical position (note: 3 Way Valve is close if the handle face same direct with dent mark on the valve), close stainless steel valve A, B, C, D, E and aluminum valve H, open fire hydrant I and stainless steel valve F; go to cabin and press down the clutch, open the PTO switch, gradually release the clutch (Note: don't release too quick, or it will ruin PTO and Gearbox), then pump start to work as mobile pump station.

Water Flowing ways: flow in from 3 ways valve G, through filter & pump, then out in Fire Hydrant I. (Valve A, B, C, D, E, F, G, H are closed)

Maintenance of water tank truck from CLW Group

1, According to the paint using requirement, before new truck using, Tank should be full filling water, and kept for five days, and then drain all water out totally. After that, flushing the coating surface, full filling the water to tank, keep for two days, and then drain out. It could load drinking water.

-----This is for the water cart which load drinking water.

2, Oftenly check the water system of the connection parts, switches and water suction hose and other parts of the sealing situation, such as once discovery of leakage, we should restore or replace seals.

3, Oftenly check tank, pump bracket, bracket fixing, all the nuts should be tightened, ensuring reliable fastening connection.

4, Oftenly check the connection of PTO and pump. It should be connected tightly and work well. If oil leakage happen, should replace the seal timely.

5, Truck waterway system is without anti-freezing device, so in cold regions, the temperature is below Zero degrees, when truck after using, it should immediately drain out all the water of water pump, water tank and water system. Pay attention to all drain plug should be tightly closed, Ensure that they are sealed up, otherwise it will affect to pump water in.

6, The paint on the tank can not be touched by gasoline and kerosene, otherwise paint will be accelerated to damage. Regularly check the quality of the paint on the tank. When the paint is damaged, it is timely to paint to prevent corrosion of the tank.

7, The medium through the ball valve should not be too dirty so as not to damage the seal ring. It is good for extending the life time of ring valve. Ball valves is no good to work for long time in a state of semi-open, otherwise the seal ring will be out of shape.

8,The pump inlet filter should be often disassemble to wash, to prevent it to be blocked.

9, Because a wooden pad installed between the tank and truck chassis, U-shape bolt will loose due to the deformation of wood glue after water cart using. So after heavy duty loading, we must regularlly tightenly U-shape bolt. Especially the new trucks must do this.

From water workshop of Chengli Special Automobile Co., Ltd